By: Ori Marom, founder, Segmentis

Container terminals worldwide have followed different paths of developments. As of today, fewer than 30 port container terminals worldwide (or, about 3%) are fully automated. The remaining 97% of port terminal are more vulnerable to major market-shocks such as the disruptions introduced by the COVID-19 pandemic and its aftermath. To address the case for accelerated automation, I propose here a general architecture for automated container-terminals that is based on recent technological advancements.

The three-pillared ecosystem and architecture

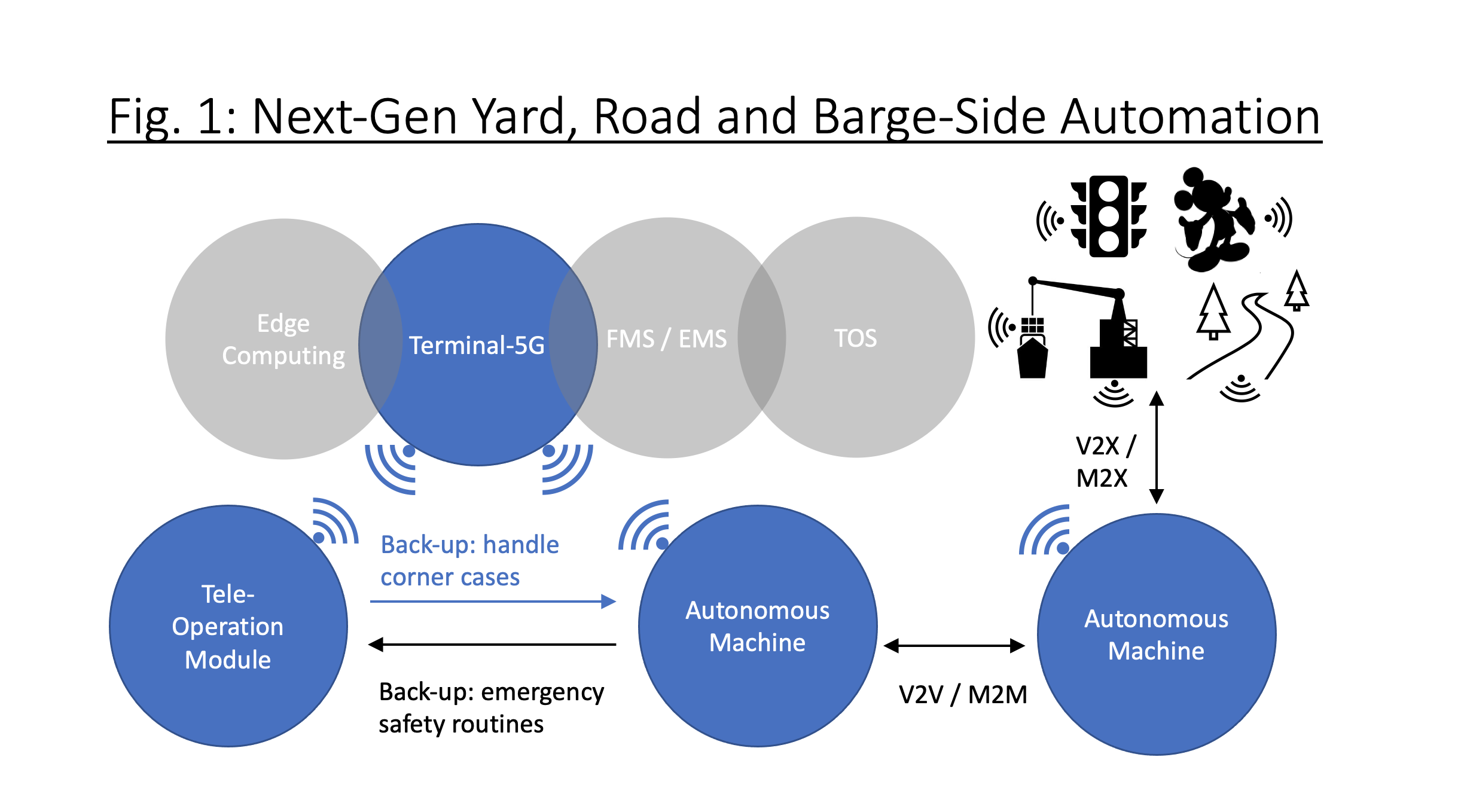

What is important to bear in mind is that port technology has changed considerably during recent years. For the better. In place of wired systems, such as fiber-optics controlled quayside cranes, new 5G enabled machines have gone completely wireless. This not only reduces expected downtime and maintenance costs but also gives rise to completely new applications of smart and connected machines. Figure 1 describes the essentials of such a terminal.

Let us begin by defining these key elements:

- Terminal-5G – is a private and fully secured, dedicated, stand-alone 5G network that covers the entire terminal grounds. Such a network must be coupled with on-premise data storage and edge-computing (the reasons for that will be discussed in a separate article, to follow).

- Tele-operation module – is a set of command and control functions that enable an operator to operate an unmanned-machine located beyond his or her line-of-sight.

- Autonomous-machine – is a machine that is able to operate without any external command or control functions within its Operational Design Domain (ODD).

To better understand what an ODD means here suppose that an autonomous straddle carrier is designed to operate in a container terminal that includes a road intersection. Consider a case when this machine, when detecting another vehicle, is designed to proceed and negotiate its way through the intersection. However, when it detects a pedestrian at the intersection, it is designed to stop and call for a remote operator. In this case, we would say that the straddle carrier’s ODD does not include autonomous interaction with pedestrians at the intersection. We would still regard it, however, an autonomous machine.

How do the parts come together?

It is posited that any successful autonomous implementation in a terminal must always have all the 3 aforementioned elements (or pillars) put together.

Why is that? I list the main reasons here:

- Full (and safe) autonomous technologies do not exist yet – in its modern sense, autonomy implies a complex ODD. While the elevator in your building is a fully autonomous system, this is not what we are concerned with here. Rather we are discussing machines which can often replace highly-skilled labor in the performance of very demanding jobs. For example, crane-operators or terminal drivers. Therefore, any autonomous yard machines should be backed by an ultra-reliable telecommunications link (hence 5G) to a remote operator.

- The use of tele-operations alone is insufficient and potentially unsafe – complex tasks such as driving a straddle-carrier through an intersection in a mixed-traffic scenario involve significant room for human errors. Therefore, autonomous backup systems should always be ready to perform safety maneuvers to avert costly and potentially dangerous mistakes. Consider for example autonomous braking systems that are implemented on modern trucks. We will need such well-designed autonomous systems also for terminal remote-control.

- Wi-Fi and 4G/LTE technologies are clearly inferior to 5G – as argued above no autonomous or remote controlled machines that can augment and empower (note, not fully replace!) skilled terminal labor should ever be allowed to operate without a secure connection. What makes 5G unique, even beyond its popularity and the consequent sheer size of investments in it, is that it allows terminals and ports to cover a given area with a very small number of cells compared to any other technology. For illustration, the Port of Southampton is reported to have replaced 200 Wi-Fi access-points with only 5 5G access-points. When a vehicle is moving through the terminal, it may roam between cells. During roaming, communication latency significantly deteriorates and this may result in diminished safety. Worse yet, a roaming vehicle could temporary lose communications altogether.

To conclude, terminal-managers are seeing increasingly effective yet highly-complex automation technologies coming to the market. Such systems and capabilities are direly needed in terminals in the aftermath of recent market shocks. I hope that the above architecture and approach can help the industry better frame the problems and potential solutions such that we could bring about together not only higher resilience to pandemics, but also an empowered port-workforce that is truly enjoying a much safer, efficient and stimulating work environment.